Three weeks on since we first wrote about the novel coronavirus. Back then, the number of global cases was nearly 200,000. That has now jumped to more than 1.7 million.

Over the course of our business continuity blog series, we’ve shed light on inefficient procurement tools, and illuminated the IT and cybersecurity pressure points amid the remote work boom.

The third instalment will see procurement and supply chain professionals step up to the challenge. But first, let’s review what they have had to deal with.

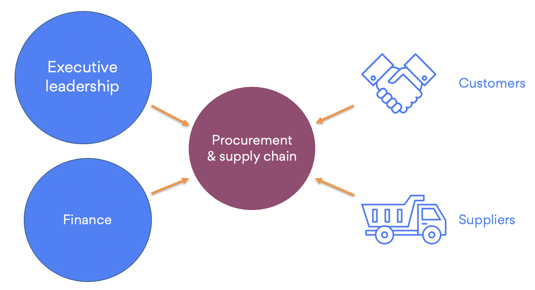

Pressure on procurement & supply chain from every direction

From the top down, they have the CEO, General Manager, the COO, and maybe even the board questioning whether the company will have enough supply to maintain its operations. Top management doesn’t want to upset the company’s big clients, so they want to know how procurement can help mitigate supply chain risk. This would help them determine contingency plans and re-prioritise projects.

On the finance side, the CFO would want to quickly run forecast for revenue and expense, ideally in a range of scenarios. He or she might want to tighten budgets, roll out a stricter approval process, and look for savings opportunities in both existing and new supplier relationships. A focus on speed and liquidity would help finance “keep the lights on.”

From the outside, suppliers want to know where the organisation stands, with existing contracts, projects and terms. They want to know how their business and cash flow will be impacted. They are as interested in their own business continuity as anyone else.

Last but not least, the company’s customers will want to know whether contractual obligations can be met. On the flipside, some may wind down temporarily, meaning a delay or shortfall in revenue.

So with all the pressure in the world, what are some strategies to help with business continuity?

Conduct end-to-end supply chain risk assessment

One might ask: “Who has the time to do a full-scale risk assessment now?”

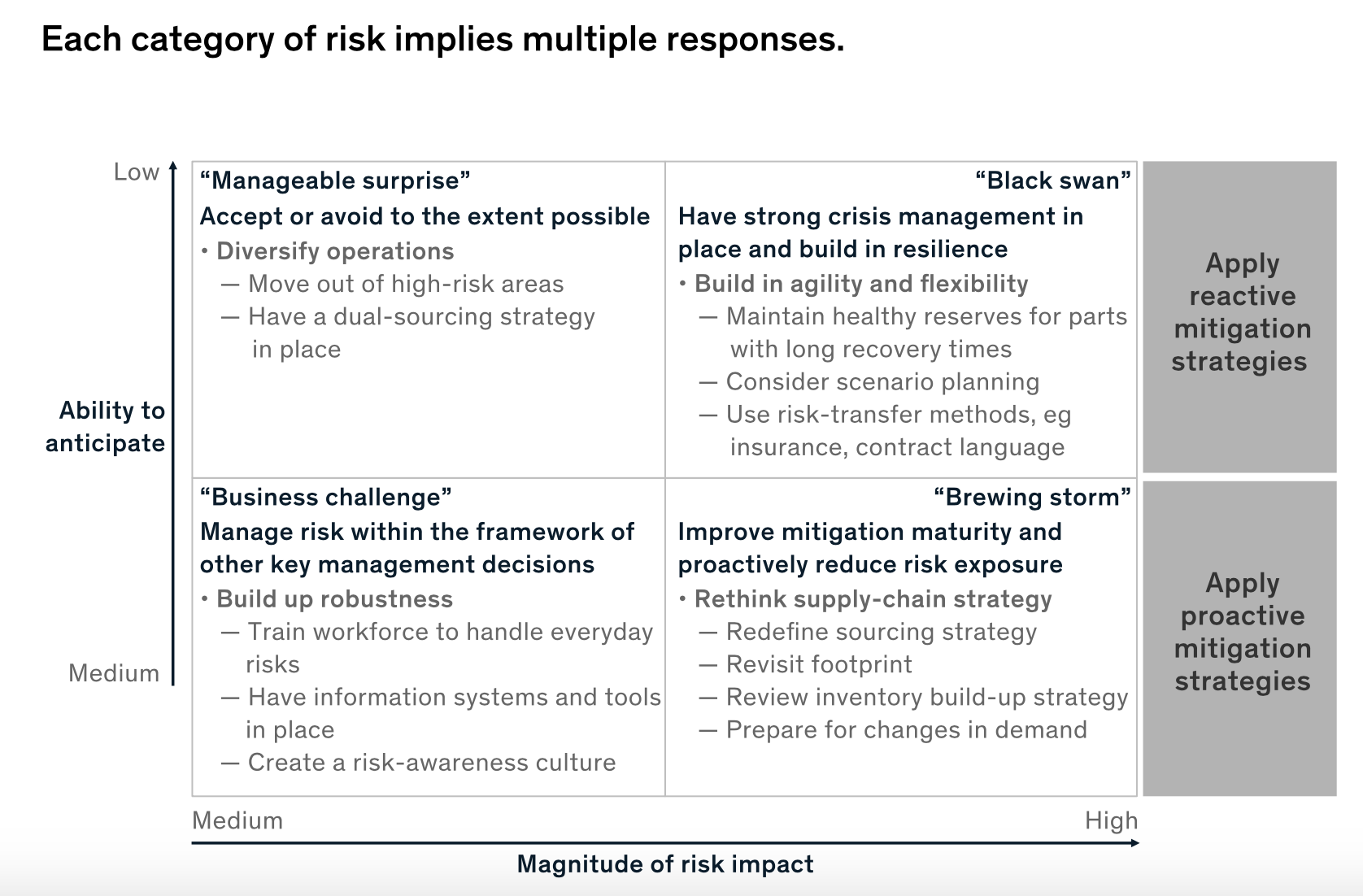

Considering COVID-19 as a “black swan” event, coming up with reactive mitigation strategies is the least one can do. In an ideal world, organisations would already have mitigation plans for each quadrant of risk as follows.

Supply chain risk quadrants. Source: McKinsey

However, the reality is that risk management has been on the back burner in many organisations. And this is a dangerous proposition for many boards. Specifically, “about 80% of Australia’s listed companies have never done scenario-planning” (Australian Financial Review).

So the focus now should be on how to accelerate the interim risk assessment exercise and gain the much-needed visibility to make the right decisions.

Some key things to remember:

- It's better to have some structure in a chaotic situation

- It may be a resource-intensive process but also a collaborative one (internal and external)

- Try to identify as many risk elements as possible, and assign likelihood/impact score

- Consider efficiency gains by adopting technology

We’ve recently hosted a webinar with Peter Deans - the risk management authority mentioned in the Australian Financial Review article above. Check it out here.

Prioritise key suppliers

Once you have captured the helicopter view, focus on the suppliers that are key to your business continuity. In other words, segment suppliers and corresponding supply chain by level of COVID-19 risk.

Then:

- Understand suppliers’ business continuity plans (e.g. by sending further questionnaires via a vendor management system)

- Understand suppliers’ enhanced health & safety plan (especially if the supply chain is mainly contractor labour who must be on-site)

- Contact high-risk suppliers, agree on supply plan, and manage performance against that plan

- Identify suppliers to reduce or eliminate

- Centralise and review contract documents, and identify actions to take if obligations can’t be met

Gather continuous supply chain intelligence:

- Monitor regional markets and government responses

- Model supply scenarios and contingency plans

- Monitor financial stability of key suppliers

Supplementary action:

- Illuminate suppliers beyond tier 1 (i.e. suppliers of your suppliers) - or the extended supply network

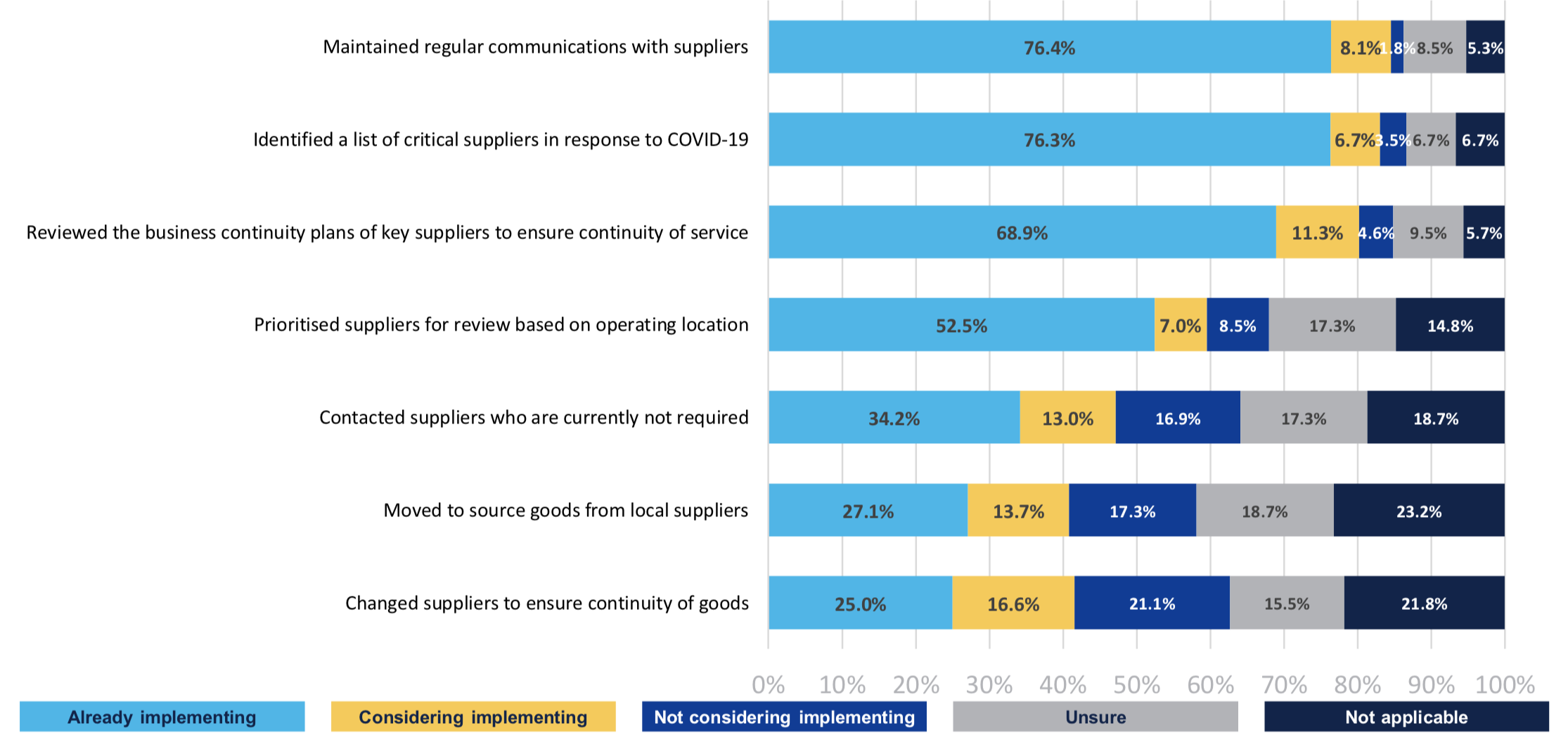

Looking for a benchmark? Here are the responses from a recent survey by the Business Continuity Institute.

Supply chain measures taken by surveyed organisations. Source: The BCI

Customer and contract management

Depending on the above analysis and arrangements you have with your suppliers, there are a few things to consider on the customer’s side:

- Evaluate contracts to identify demand impact, and cancellation or delay actions

- Identify new demand (e.g. an emergency project) that you can quickly garner/re-shuffle supply for

Diversify or expand supply network

Borrowing from the manufacturing world, increasing buffers in times like this will ensure a better chance of business continuity.

It might lead to higher costs at first glance but the cost of doing nothing (leading to an actual halt) is much higher.

As we have mentioned previously, paper-based or manual procurement processes will hinder more than help. The following mitigation strategies all require speed and agility:

- Execute rapid sourcing for incremental needs - there is no better time to transition towards/ramp up digital RFx processes

- Accelerate the qualification process for alternative suppliers

- Identify and tap new supply networks (e.g. construction marketplace)

Maintain fraud and vendor management safeguards

Whilst there is a need to act fast, it doesn’t mean rushing. Organisations still need to practice supplier due diligence, if not more so, in the current climate.

- Don’t skimp on pre-qualification and collecting compliance documents, keeping a close watch on expiry dates

- Speed up the process while ensuring shared visibility by adopting a cloud-based vendor relationship management system. If you already have one in place, now is the time to utilise it to the full extent as people adjust to the remote work environment.

Social responsibility

The current pandemic has exposed both the bright and dark side of humanity. Indeed, organisations don’t want to be on the wrong side of history if they are to continue into the recovery phase.

Depending on each business’ financial capability, here are some actions to consider:

- Partner with strategic suppliers to mitigate impact on employees and communities

- Explore smaller or local suppliers (e.g. social enterprises)

- Pay suppliers quicker than the standard terms

- Consider a business case for circular procurement

Long-term supply chain and risk mitigation considerations

“If you want to be prepared for the occurrence of a random risk, then you have to make investments and decisions upfront, before the event.”

As businesses get through the near term, there are already calls for some old supply chain lessons to be re-learned. Namely:

- Resilience over cost optimisation

- Treat the cost and risk trade-off very carefully

- Have plans for different time horizons and scenarios

That means, to prepare for a similar crisis in the future, now is the time to start applying the learnings from COVID-19, not afterwards.

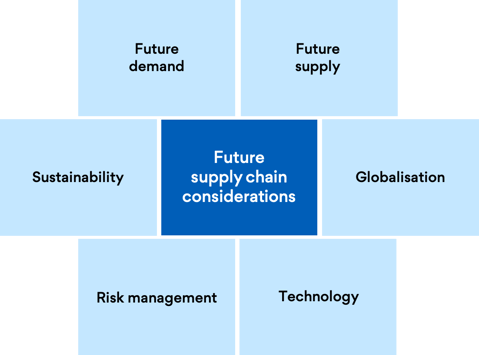

Organisations can even start a “plan-ahead” team working alongside the crisis response team. Broadly speaking, there are 5 elements to consider when redesigning the supply chain for resilience:

Based on an understanding of these elements, organisations can:

Revisit the category strategy

- Adopt multi-sourcing

- Adopt multiple segmentation strategies of supplier database (e.g. by risk, performance etc.)

- Reprioritise project pipeline and assess impact on projected savings

- Re-evaluate the supplier evaluation criteria

- Enhance transparency and visibility across the extended supply network

- Get acquainted with scenario planning techniques (our recent risk mitigation webinar can be a useful resource)

Accelerate technology adoption

- The current crisis might have accidentally given the much-needed nudge towards digital tools adoption. It might even make change management a lot easier.

- As the boundaries between working and living space close, the technologies used in the two realms will either start to share the same standards in user experience and mobility, or the gap would become so big that workplaces have to adapt in order to keep morale and productivity high. Either way, clunky on-premise system or spreadsheets just won’t cut it anymore.

---

This is the end of our three-week series around business continuity planning. Let’s keep the conversation going by commenting below, following us on social or reaching out directly to our team. We are all in this together.

Related Articles

Questions to ask when managing supply chain through COVID-19 and beyond

Whilst many countries and organisations are edging towards the next phase with recovery in mind, it might be a useful exercise to re-visit some questions that should have been asked a few weeks ago. And if they were asked, were there sufficient answers or solutions provided by technology?

Back to basics: Vendor Management in high risk supply chains

The concept of engaging external parties to do work for your business is probably as old as the concept of business itself. The inherent us vs. them relationship means there are often procedures, documents, and checkpoints, to make sure the vendor does things in your best interest.

ESG in construction: A story in statistics

With labour shortage, increasing costs and tightened margins as the backdrop, ESG could be one of the last things on your mind.

Let's stay in touch

Get the monthly dose of supply chain, procurement and technology insights with the Felix newsletter.