The Australian construction industry is at a turning point as the number of projects increases while productivity decreases. Experts tout the current state of inefficiency is due to the industry’s stagnant operations being unable to manage the shortages and uncertainty in its supply chain. History shows us that this state indicates an industry ready for disruption.

Disruption is necessary to shift the industry towards more sustainable and productive practices, but where can this change come from? With so much uncertainty coming externally from the supply chain, organisations should look internally to improve their procurement practices, strengthen operations and uncover sources of disruption.

Disruption, what?In other industries, disruption has come from new entrants bringing innovative technology, business models or value networks which have forced incumbent organisations to adapt to new sources of competition.

Industries such as healthcare or telecommunications have experienced product led disruption but it’s unlikely construction will find disruption coming from new products or materials.

Instead, disruption will come from existing organisations that are able to adopt new technologies and innovate their value networks to outperform their competitors.

Disruption, how?

Given that the industry’s greatest source of pressure is from the supply chain, it makes sense that procurement is where organisations should begin their journey to disrupt. Procurement in construction has evolved little past spreadsheets and processes that only last the lifetime of a project. Yet entire projects succeed based on their ability to source and deliver requirements on time and within budget.

There is tremendous opportunity to disrupt stagnant operations by adopting new procurement strategies, improving the efficiency of procurement processes and strengthening supplier relationships.

As first-movers in this quest for disruption in construction, the big question is how do you start?

Start with dataTo uncover new procurement strategies and sources of efficiency, construction needs to first look within. In construction especially, the procurement function has large amounts of data which can be analysed to discover opportunities for disruption. The challenge is that this data is often siloed and unavailable for in-depth analysis. The more projects a contractor has, the greater the data they have at their disposal, but this data is spread out across a number of projects.

The first step should be to centralise, standardise and consolidate procurement data. The challenge that procurement teams face when aggregating data for analysis is that different projects and teams have different processes and practices for recording information.

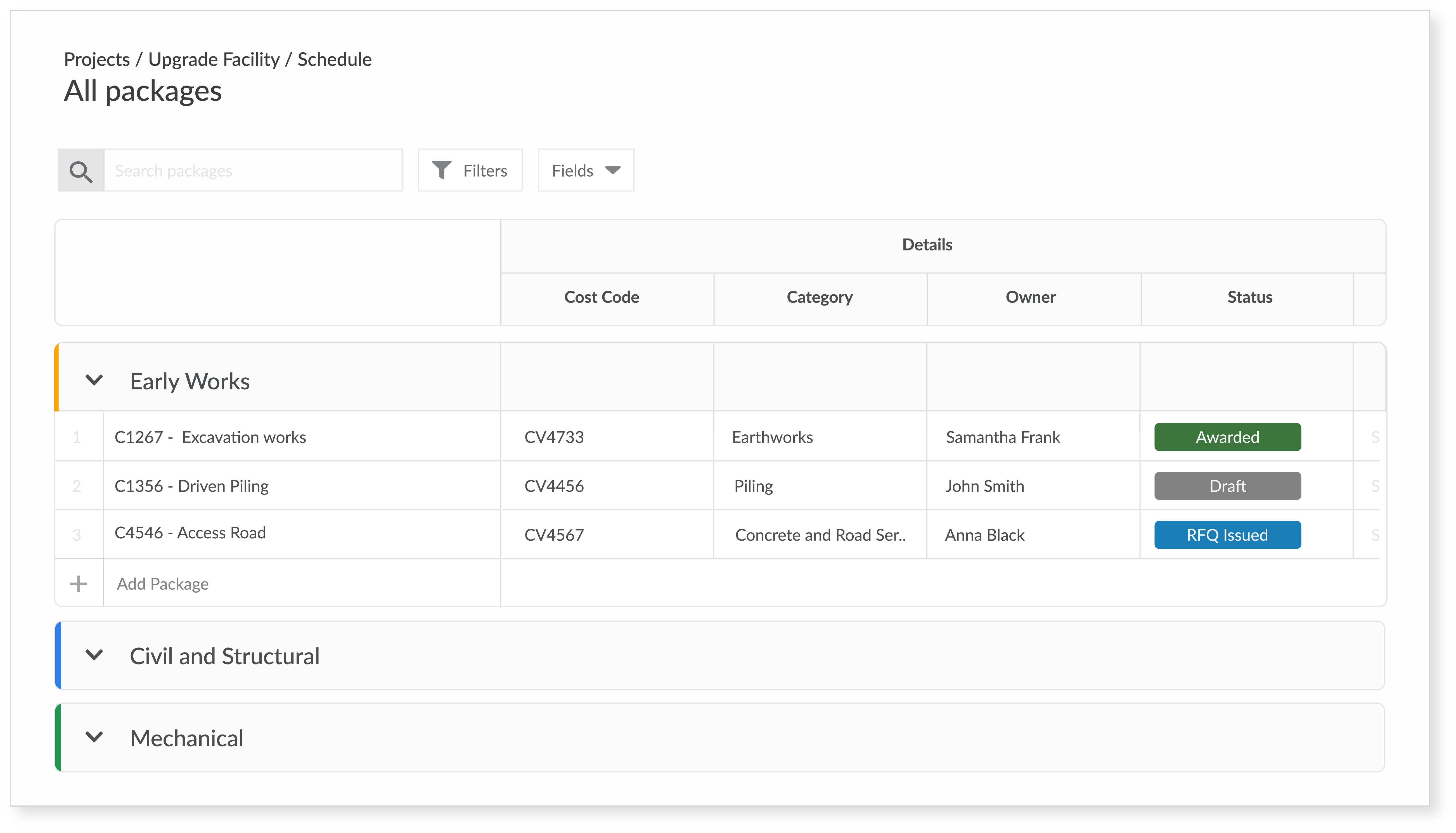

By standardising procurement processes and information, data can be aggregated and analysed. The most reliable way to do this is to provide procurement teams with a common system to manage sourcing activities.

One reason procurement data is fragmented is because ERPs aren’t designed to manage procurement. A challenge organisations will face is whether to build or buy a system to manage procurement.

The advantage of building an in-house procurement system or customising an ERP is that it can be designed to meet the specific needs of an organisation.

The advantages of adopting a purpose-built procurement management system are speed and cost. Implementing a procurement management platform, like Felix, takes weeks rather than the months or years it will take to build an in-house system. The total cost of ownership is likely to be far less when adopting a dedicated procurement management platform and integrating it with existing systems.

Whilst Felix is built for construction and will accommodate most organisation’s procurement processes, it can be customised further to suit specific requirements.

Once procurement activities and data are centralised, the search for disruption can truly begin. With aggregated data across projects it is much easier to analyse processes, contracts and suppliers to identify opportunities for disruption.

At this point disruption can take many forms depending on existing processes, project portfolios and organisational structure.

Contracts could be restructured to better accommodate the risk from shortages and delays, procurement activities could be centralised to increase bargaining power, supplier panels can be strengthened based on past performance or a more agile sourcing model developed to cater to dynamic ESG requirements.

Disruption is a complex process, compounded by the fact that we don’t know what the end result will look like. The best way to tackle uncertainty is with stability, and systems are the best way to deliver predictable and consistent outcomes. Implementing procurement systems and then harnessing the data will provide the insights required for disruption.

The organisations that set themselves up for success now will be in the best position to disrupt their value networks and strengthen their supply chain.

----

Want to see Felix in action? Feel free to request a demo here.

Related Articles

Procurement & supply chain teams urged to learn from Australia’s recent underpayment scandals

Top retail executives have blamed offshore software not configured for “Australia's relatively complex labour environment as a key factor in staff being underpaid.”

Felix - The Year in Review

Felix has had one for the record books this past financial year. With more product releases than ever before, new partnerships with some of Australia’s leading Tier-1 organisations, and a team that continues to grow exponentially, this year Felix has taken a major step to becoming one of Australia’s leading procurement technology providers.

In this blog I will provide you with some highlights from the past year, along with a sneak peek into our future.

Webinar recap: Introducing Procurement Schedule

Recently, I had the pleasure of unveiling our latest module Procurement Schedule in our launch webinar. Below are the highlights of the session.

Let's stay in touch

Get the monthly dose of supply chain, procurement and technology insights with the Felix newsletter.